Simple Explanation of DC Motor Working Principle

The DC motor is a core device in the modern world, efficiently transforming electrical energy into mechanical rotation. For JEE Main aspirants, grasping the physics of this conversion not only boosts conceptual strength, but also helps solve circuit and electromagnetism problems. An understanding of DC motors lays the foundation for real-world applications like robotics, electric vehicles, and precision tools.

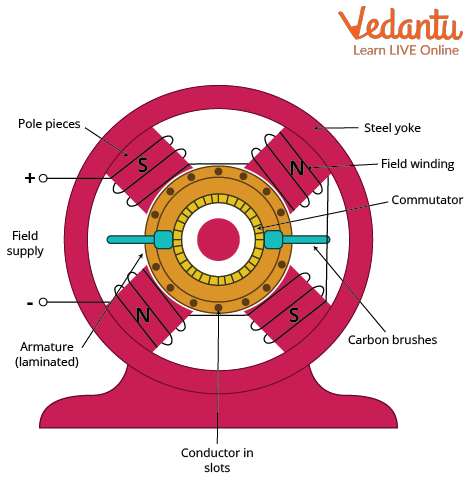

Essential Construction: Internal Features of a DC Motor

At its heart, a DC motor contains two main magnetic field sources—the stator and the armature. The stator generates a fixed magnetic field, often using permanent magnets or field windings. The armature is a coil mounted on a rotating shaft, receiving current from the supply. Brushes and a commutator interface between the external circuit and the rotating coil, allowing unidirectional torque. This construction is central to achieving constant rotational direction, even as the coil moves through changing magnetic polarities.

DC Motor Principle: How Electromagnetism Powers Rotation

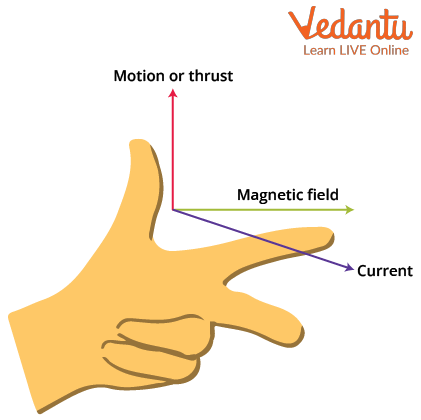

The working of a DC motor is grounded in the law of electromagnetic induction and the Fleming’s left-hand rule. When current flows through the armature conductors, it interacts with the stator’s magnetic field. A force is produced on each segment as per the Lorentz force law, creating a net torque about the shaft. The direction of this force, and hence the direction of rotation, is given by arranging your thumb, forefinger, and middle finger perpendicular according to Fleming’s convention: Thumb—motion, Forefinger—field, Middle finger—current.

Detailed Working of DC Motor: The Role of Commutator

As the armature rotates within the magnetic field, the current direction in each armature coil must be reversed every half-turn. The commutator achieves this by switching connections, ensuring that torque always acts in a single rotational sense. Carbon brushes maintain good electrical contact and reduce wear. The continuous interplay between current and magnetic fields is what keeps the shaft spinning in classic DC motors.

Types of DC Motors for JEE Main Context

For examinations, students should distinguish between the main types based on armature-field winding interactions:

- Permanent magnet DC motor—uses permanent magnets in stator

- Separately excited DC motor—armature and field coils have independent supplies

- Series wound DC motor—field winding in series with armature

- Shunt wound DC motor—field winding parallels armature

- Compound wound—mix of series and shunt configurations

Each design alters speed-torque characteristics and application scope.

Torque Production and Mathematical Formulation in DC Motor

To understand how torque is developed, consider a single armature conductor of length l, carrying current I, in a magnetic field of flux density B. The force experienced is F = BIl (for perpendicular arrangement). If the armature has z total conductors and rotates with radius r, then total torque develops as:

Torque, T

= Force × Radius

= (Total force on all conductors) × r

= (B × I × l × z) × r / (2πr)

= (P × ϕ × z × I) / (2π × a)

Where P is the number of poles, ϕ the flux per pole, and a the parallel paths. Thus, T = (P ϕ z I) / (2π a) is the key expression. Torque is directly proportional to armature current and magnetic flux.

Practical Uses of DC Motor in Everyday Life

DC motors are essential in applications requiring smooth speed control and stable torque at varied loads. They are used in electric traction for trains and vehicles, industrial conveyors, portable tools, model trains, and precision actuators in robotics. Their ability to offer instant response and variable speed makes them indispensable in modern automation.

Physics Connections: DC Motor in JEE Main Syllabus

For JEE Main preparation, the Working Principle of DC Motor links directly to Electromagnetic Induction and Alternating Currents and Current Electricity, making it vital to master both circuit analysis and magnetism segments.

A strong conceptual hold also supports understanding of Electricity and Magnetism and comparison with AC machines, as covered in related Vedantu JEE Main resources.

Vedantu Tip: How to Approach DC Motor Questions

Always start by sketching the schematic and marking the field and current directions. Apply the left-hand rule for force analysis. Learn the basic formulae for torque and EMF, and practice problems that integrate circuits, fields, and rotation. With NCERT pattern exercises and Vedantu’s structured study modules, confident problem-solving is well within reach.

FAQs on How Does a DC Motor Work?

1. What is the working principle of a DC motor?

DC motors work on the principle that a current-carrying conductor placed in a magnetic field experiences a force which causes motion. The essential points are:

- An electric current passes through the motor armature.

- The armature is placed between the north and south poles of a permanent magnet or electromagnet.

- This setup creates a force (as described by Fleming's left-hand rule), resulting in rotational motion.

2. What is Fleming's left-hand rule and how does it apply to DC motors?

Fleming's left-hand rule helps determine the direction of force experienced by a conductor in a magnetic field.

- Hold your left hand with the thumb, forefinger, and middle finger perpendicular to each other.

- The forefinger points in the direction of the magnetic field (N to S), the middle finger shows the direction of current, and the thumb points in the direction of motion (force).

3. Why is a commutator used in a DC motor?

A commutator is a key part of a DC motor used to reverse the direction of current through the armature windings, ensuring continuous rotation.

- Keeps the torque direction constant for smooth rotation.

- Switches current supply in synchrony with coil’s rotation.

4. What is the main function of a DC motor?

The main function of a DC motor is to convert electrical energy into mechanical energy.

- This enables a wide range of applications such as fans, toys, and electric vehicles.

- Mechanical work is achieved by the rotation of the armature inside the magnetic field.

5. What are the essential parts of a DC motor?

The basic components of a DC motor include:

- Armature (rotor): Rotating coil or winding where current flows.

- Stator: Provides stationary magnetic field (using magnets or windings).

- Commutator: Reverses the direction of current in the armature.

- Brushes: Conduct current between external circuit and rotating commutator.

6. How does a DC motor convert electrical energy to mechanical energy?

A DC motor converts electrical energy to mechanical energy by using electromagnetic forces.

- When current passes through the armature winding in a magnetic field, it experiences a force.

- This force creates rotational motion due to the arrangement of the magnetic field and the armature.

7. What happens when the direction of current in a DC motor is reversed?

When the direction of current in a DC motor is reversed, the direction of the force on the armature (and thus its rotation) is also reversed.

- According to Fleming’s left-hand rule, this changes the direction of motion.

- It is possible to change the rotational direction of the motor as desired by reversing the current.

8. State the applications of a DC motor.

DC motors are widely used due to their efficient mechanical work and easy speed control.

- Electric fans and pumps

- Toys

- Lifts and cranes

- Electric vehicles

- Industrial machines

9. What are the advantages of DC motors over AC motors?

DC motors offer several advantages compared to AC motors:

- Simpler speed control and direction reversal.

- High starting torque.

- Preferred for applications requiring variable speed.

10. What is meant by back EMF in a DC motor?

Back EMF is the electromotive force generated in the armature winding of a DC motor due to its rotation in the magnetic field.

- It acts in opposition to the applied voltage.

- Back EMF helps self-regulate the speed and protects the motor from overcurrent.

11. What are the limitations of DC motors?

While DC motors are versatile, they have some limitations:

- Need for regular maintenance (wear and tear of brushes and commutator).

- Lower efficiency in large-scale industrial applications compared to AC motors.

- Limited power output for very large loads.

12. Why are brushes used in DC motors?

Brushes in a DC motor are used to conduct electric current between the stationary external circuit and the rotating commutator.

- They allow current to enter the rotating armature windings.

- Ensure continuous energy transfer for smooth motor operation.