How Does a Block and Tackle System Make Work Easier?

The block and tackle system is an arrangement of multiple pulleys designed to reduce the effort required for lifting heavy loads by increasing mechanical advantage. This concept is essential in mechanics, especially for JEE Main, as it illustrates the application of simple machines to achieve force multiplication using rope and pulley arrangements.

Block and Tackle System: Definition and Construction

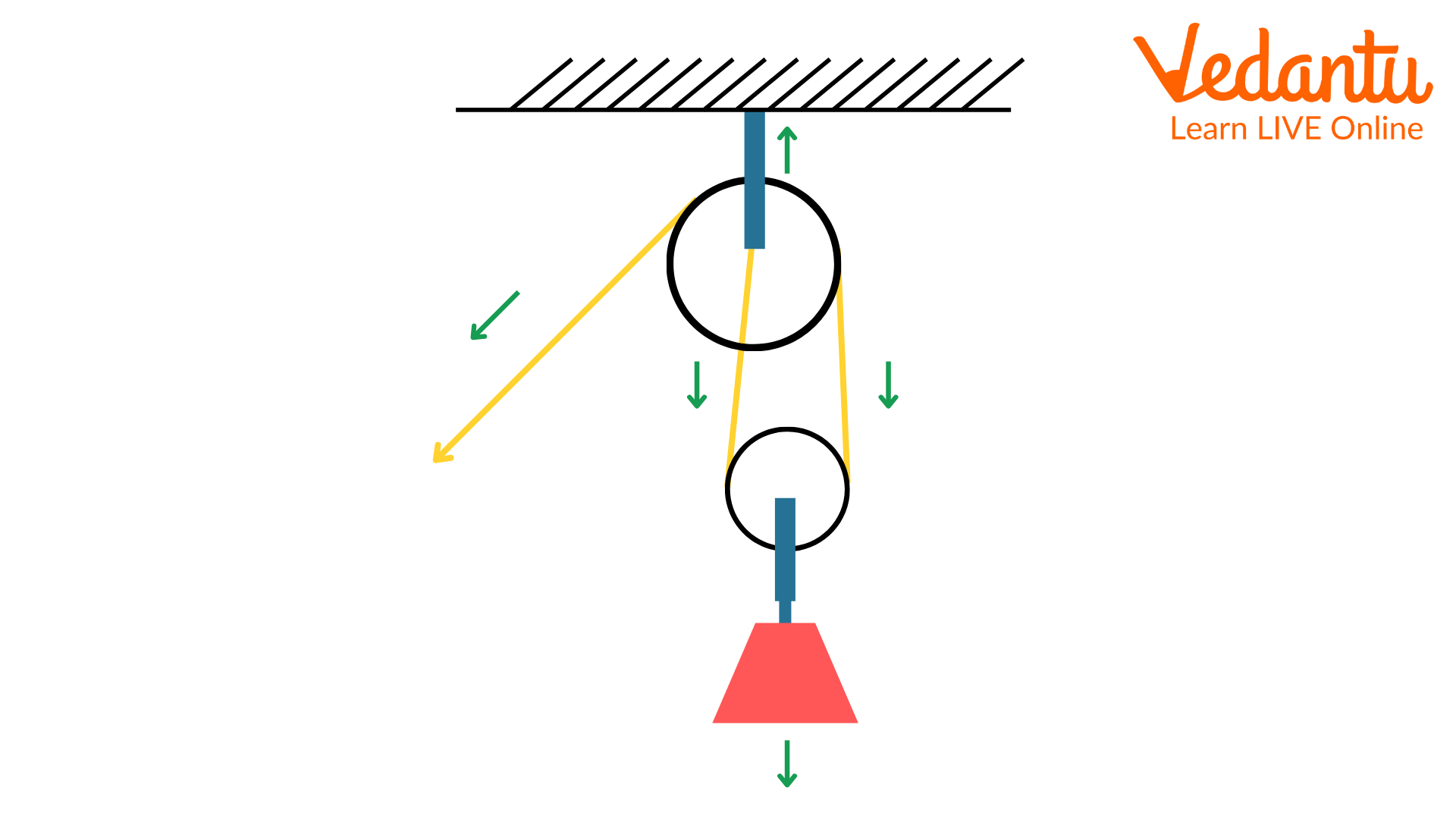

A block and tackle system consists of two or more pulleys assembled as blocks, joined by a continuous rope or cable. One block is usually fixed, while the other is movable and attached to the load. The rope passes through the pulleys to provide a mechanical advantage, enabling heavier loads to be lifted with less applied force.

Mechanical advantage in the block and tackle system depends on the number of supporting rope segments between the pulleys. The use of more pulleys increases the force multiplication and reduces the effort needed. This principle is integral in devices such as cranes and elevators.

Pulley: Basic Concept

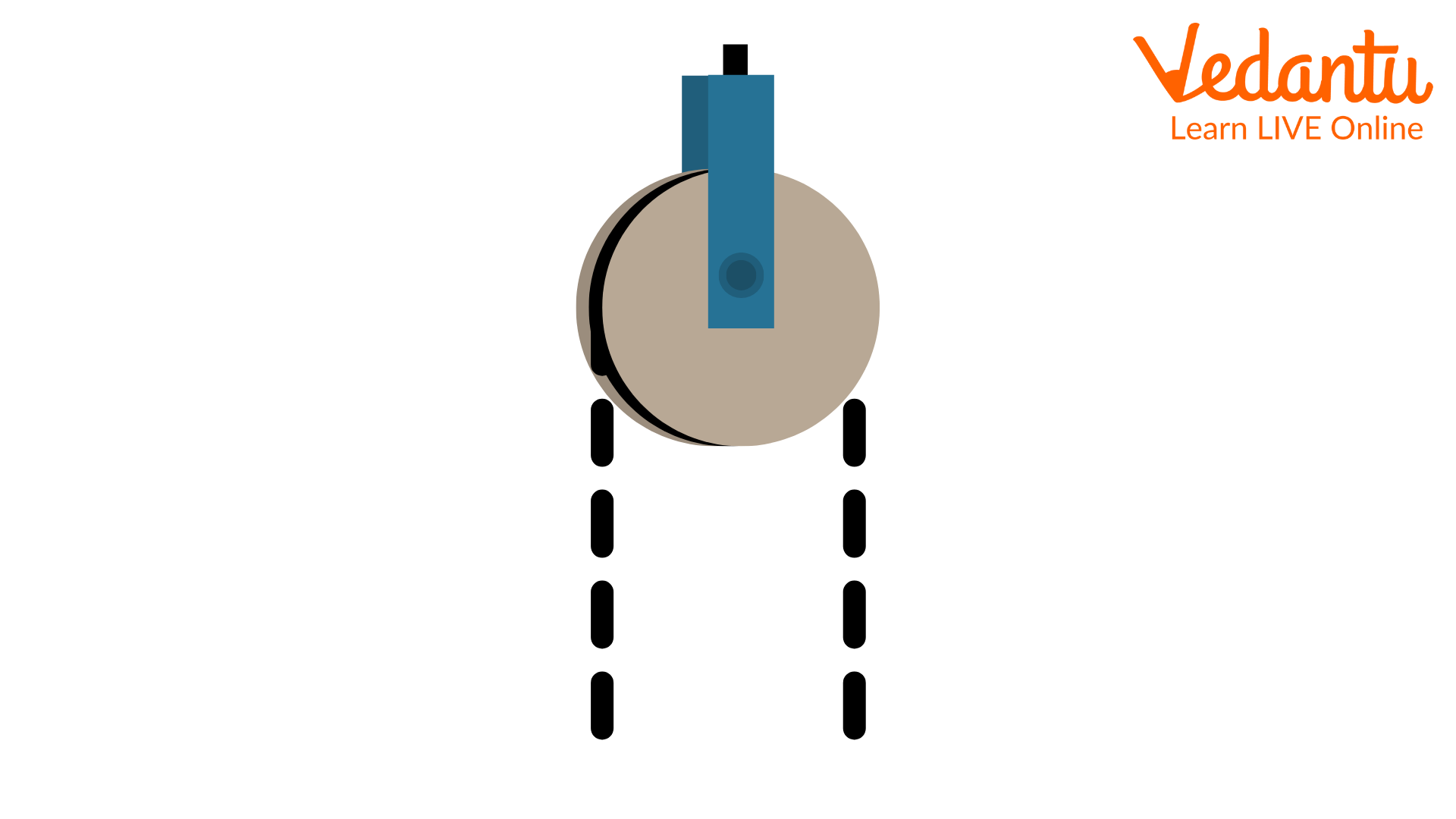

A pulley is a simple machine consisting of a wheel on an axle, designed to guide a rope, cable, or belt. The groove on the pulley keeps the rope aligned, ensuring smooth movement for lifting loads. In a block and tackle system, pulleys combined into blocks increase lifting efficiency.

Understanding pulleys is fundamental in analyzing mechanical advantage, force directions, and velocity ratios, all relevant when studying advanced work and energy topics in Work, Energy, and Power Concepts.

Types of Pulleys in Block and Tackle Systems

Block and tackle systems may use three primary types of pulleys: fixed, movable, and compound. Fixed pulleys alter the direction of the applied force but do not reduce effort. Movable pulleys provide mechanical advantage by sharing load support over multiple rope sections. Compound pulleys, also called block and tackle systems, use combinations of fixed and movable pulleys to maximize mechanical advantage.

By properly combining fixed and movable pulleys, the system distributes weight, lowers the applied force required, and increases efficiency in lifting operations. The design and arrangement depend on the load and desired velocity ratio.

Mechanical Advantage and Velocity Ratio

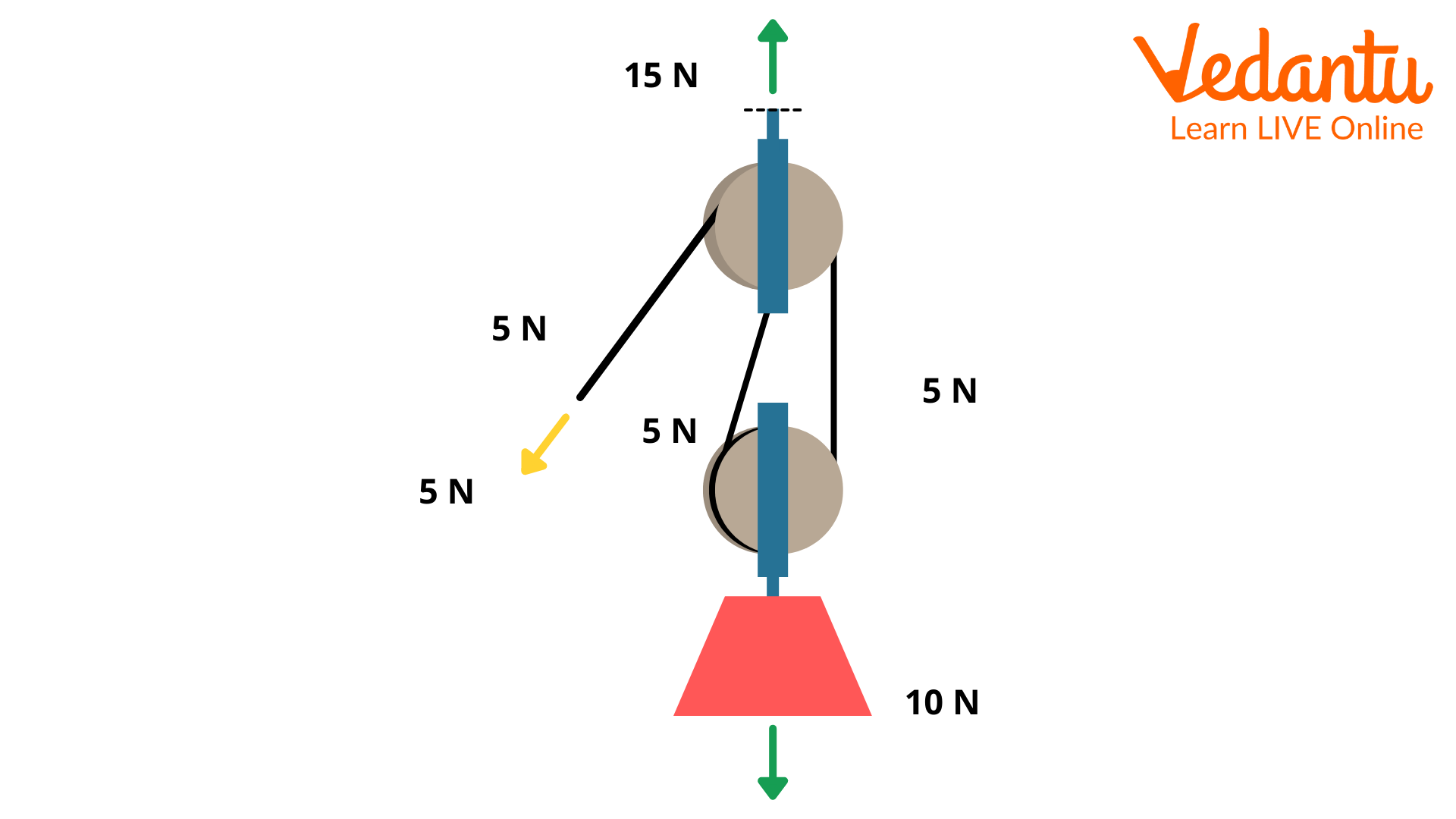

Mechanical advantage (MA) in a block and tackle system is defined as the ratio of the load lifted to the effort applied. For an ideal system with n supporting rope segments, the theoretical mechanical advantage is:

$MA = n$

The velocity ratio (VR) describes the relationship between the distance moved by the effort and load. In an ideal block and tackle system, $VR = n$. Therefore, with more pulleys, the effort required decreases proportionally as the mechanical advantage increases. For example, in a system with three pulleys, $MA = 3$, and $VR = 3$.

Actual mechanical advantage is lowered by friction and the rigidity of the rope. The efficiency ($\eta$) of the system is given by:

$\eta = \dfrac{MA}{VR} \times 100\%$

This relationship is crucial when evaluating real-world applications and energy loss in mechanical systems. For an in-depth discussion on related concepts, see Understanding Levers in Physics.

Equilibrium Conditions in the Block and Tackle System

For a block and tackle system to remain in equilibrium, the sum of forces acting on the movable block must be zero. The tension throughout the rope is uniform in an ideal system. Each segment supporting the load contributes equally, with the load divided among the rope portions passing to the movable block.

Newton’s laws are applied for force analysis, ensuring that the system is stable and enabling precise calculation of effort for various system configurations.

Common Block and Tackle Arrangements and Their Velocity Ratios

Block and tackle systems are often described by the number of pulleys used. The velocity ratio depends on the configuration and directly influences the required lifting effort.

| System Type | Velocity Ratio (VR) |

|---|---|

| 2-Pulley Block and Tackle | 2 |

| 3-Pulley Block and Tackle | 3 |

| 4-Pulley Block and Tackle | 4 |

| 5-Pulley Block and Tackle | 5 |

| 6-Pulley Block and Tackle | 6 |

The velocity ratio determines the distance the effort moves relative to the load, ensuring effective force multiplication for different mechanical setups.

Example: Analysis of a Two Pulley Block and Tackle System

In a two pulley block and tackle system, the rope passes through both pulleys so that pulling a length of 2 meters on the effort side lifts the load by 1 meter. The applied effort is thus half the total load weight in an ideal scenario. This setup clarifies how the system multiplies force while maintaining constant energy output.

When evaluating block and tackle systems, consider the efficiency losses due to friction and real material properties. For problems involving friction between blocks, see Block on Block Problems with Friction.

Applications of Block and Tackle Systems

Block and tackle systems are utilized in lifts, cranes, and industrial hoists. Their primary function is to allow the lifting of heavy weights with manageable effort. The block and tackle concept extends to many engineering and physics problems involving force systems, such as those encountered in Understanding Torque in Physics.

These systems are also pivotal in mechanical engineering, notably where controlled motion in a vertical plane is essential, including various real-world and exam-oriented problems. For rotation-based force systems, hold relevance to Centrifugal Force in Physics and Motion in a Vertical Circle.

Key Points on Block and Tackle Systems

- Uses multiple pulleys for mechanical advantage

- Reduces required effort for lifting loads

- Mechanical advantage equals number of supporting ropes

- Velocity ratio defines input-output motion relationship

- Efficiency decreases with frictional losses

- Applied in cranes, lifts, ships, and engineering

Mastering the block and tackle system enhances understanding of simple machines and force multiplication, both fundamental for advanced physics and engineering studies.

FAQs on Understanding the Block and Tackle System

1. What is a block and tackle system?

A block and tackle system is a mechanical arrangement of pulleys (blocks) with a rope or cable threaded between them, used for lifting or moving heavy loads with less effort.

- The system increases mechanical advantage by distributing the load over multiple pulleys.

- It commonly includes a fixed pulley and a movable pulley.

- This setup reduces the input force needed to lift or move objects.

2. How does a block and tackle system work?

A block and tackle system works by using multiple pulleys to redirect the force applied to lift or move a load, making the task easier.

- Rope or cable is passed through the pulleys in a specific arrangement.

- When force is applied, each pulley reduces the overall effort required.

- This allows a user to lift heavier loads than would be possible with a single pulley.

3. What are the main components of a block and tackle system?

The key components of a block and tackle system are:

- Blocks (sets of pulleys fixed together)

- Ropes or cables threaded through the pulleys

- Fixed block (attached securely in place)

- Movable block (moves with the load as it’s lifted)

4. What is the mechanical advantage of a block and tackle system?

The mechanical advantage (MA) of a block and tackle system is the ratio of the output force to the input force, allowing you to lift heavier loads with less effort.

- MA = Number of rope segments supporting the load

- More pulleys mean greater mechanical advantage

- This reduces the input force needed for lifting

5. What are the uses of block and tackle systems?

Block and tackle systems are widely used wherever heavy lifting is required.

- Raising sails on ships

- Lifting engines in garages

- Used in cranes, construction sites, and rescue operations

- Moving cargo and goods efficiently

6. What are the advantages of using a block and tackle system?

Block and tackle systems offer several advantages, making lifting tasks more efficient.

- Reduce the amount of force needed

- Enable lifting of very heavy objects safely

- Increase mechanical advantage with more pulleys

- Easy to operate in practical applications

7. How do you calculate the mechanical advantage of a block and tackle system?

The mechanical advantage of a block and tackle is calculated by counting the number of rope segments supporting the movable block.

- MA = Number of supporting ropes

- If there are four rope segments, the MA is 4

- The input force is divided by the mechanical advantage to get the force needed

8. What is the efficiency of a block and tackle system?

Efficiency is the ratio of useful work output to input work, expressed as a percentage.

- Efficiency (%) = (Load lifted × Distance moved) / (Effort applied × Distance pulled) × 100

- Friction between pulleys and rope reduces efficiency

- Well-maintained systems are more efficient

9. Name two factors that reduce the efficiency of a block and tackle system.

The efficiency of a block and tackle system is reduced by:

- Friction between rope and pulleys

- Stretching or slipping of the rope

- Poor lubrication and worn-out pulley bearings

10. State one principle on which the block and tackle system works.

The block and tackle system works on the principle of the mechanical advantage of pulleys, which allows a smaller effort to lift a larger load by using multiple pulleys.

- It distributes the weight across segments of rope

- Reduces the force needed for lifting