Why Understanding Sugar Production Matters in Everyday Life

Globally sugar is used as a sweetener. Things such as candy and soda taste good and sweet after adding sugar to them. Mostly the sugar used by people is known as sucrose. Sucrose is present in almost every plant. The sugarcane plant and sugar beets are the best sucrose producers. Most of the sugar present in the world is produced from them. The sugarcane plant is a giant, thick grass.

Majorly sugarcane is produced in countries like Brazil, India, and China. The sugar beet is one type of beet. The sugar is stored in its white root. France and Germany are called the leading producers of sugar beets.

Sugar Making Process

The Sugar Factory

Let's see how sugar is made. Most commercial sugar is white granulated sugar that is processed in refineries, beet-sugar factories, or cane-mill white-sugar factories. These sugars are classified according to their grain size as extra-coarse, coarse, standard, fine, or extra-fine granulated. For plants, the source of sugar is the energy they produce through photosynthesis. The grain size of the extra-coarse granulated sugar is larger than that of 1.0 millimetres. At the same time, the extra-fine granulated is less than 0.25 millimetres. You might have a question that sugar is made from which plant? Sugar is majorly made from the sugar cane plant and sugar beet.

Production of Sugar

Production of Sugar

The various kinds of sugar are produced through slightly different processes than those used for white granulated sugar. The soft yellow and soft brown sugar are produced by retaining some of the molasses during the processing. These sugars are soft and clingy due to the molasses film containing about 35 times more water than that of the refined white sugar.

The variety of sugar includes English coffee sugar, a large brown crystal with a characteristic caramel flavour. The English coffee sugar is made from the successive boilings of refinery liquid. The candy sugar consists of large white sugar crystals. It is slowly crystallised from the very pure liquid during sugar processing and is mainly used by the brewing industry.

Sugar

Sugar

Sugar is one of the purest ingredients and a natural carbohydrate that is present in fruits, vegetables, and nuts. The sugar is produced from sugar beets, root vegetables that grow in cooler climates, and sugar cane plants. The green plants produce sugar through a process called photosynthesis. Photosynthesis is a natural process that turns sunlight into energy.

Sugarcane Plant

Sugarcane Plant

The sugarcane plant is a tropical grass that grows up to 20 feet tall. The sugar beet and the sugar cane are the go-to sources for sugar since they have the highest percentage of sucrose of all plants. For sugar cane and sugar beet, the refining process removes all the impurities and the surrounding plant matter and leaves only pure sucrose. Today, we’re looking forward to the process for the sugar cane and how it gets from the field to your kitchen pantry.

Refined Sugar

Refined sugar is one of the highest quality products you can find at a grocery store since it is 99.9% sucrose. Throughout the process of manufacturing, the sugar is tested for its purity, sucrose content, proper pH balance, temperature, colour, and consistency. The monitoring of equipment and filtering of the materials make sure that they are working efficiently.

Different Types of Sugar Forms

Summary

Globally, sugar is the most widely used sweetener. So much sugar can result in weight gain and tooth decay. The doctors suggest that people have a note on how much sugar they eat.

Today some people take artificial sweeteners such as saccharin and aspartame instead of sugar. These sweeteners are especially popular with people trying to lose their body weight. At the same time, some doctors suggest that artificial sweeteners are not safe for our health.

FAQs on How Is Sugar Made? Step-by-Step Process for Kids

1. What is sugar and where does it primarily come from?

Sugar is a sweet-tasting substance that we use in our food. Most of the world's sugar is made from two main plants: sugarcane, which is a tall grass, and sugar beet, which is a root vegetable. These plants store a large amount of natural sugar in their stalks and roots, respectively.

2. How is sugar made from sugarcane step-by-step?

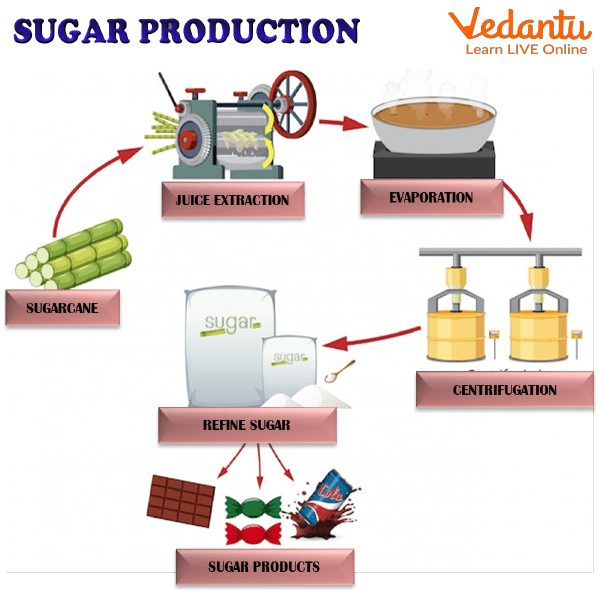

Making sugar from sugarcane involves several key steps in a factory:

Harvesting and Cleaning: First, sugarcane stalks are cut from the fields and cleaned with water.

Crushing: The clean stalks are crushed by large rollers to squeeze out the sweet, watery juice.

Boiling and Evaporation: The juice is heated in large vats. This makes most of the water evaporate, leaving behind a thick, sticky syrup.

Crystallisation: The thick syrup is cooled down. As it cools, tiny sugar crystals start to form.

Separating and Drying: The sugar crystals are separated from the remaining liquid (molasses) and then dried. The final product is the white or brown sugar we use.

3. What is the main difference between white sugar and brown sugar?

The main difference between white and brown sugar lies in a substance called molasses. Both sugars come from the same sugarcane plant. However, white sugar is highly refined to remove all the molasses, making it pure white. Brown sugar is less refined and retains some of this dark, sticky molasses, which gives it a brownish colour, a slightly moist texture, and a caramel-like flavour.

4. Why do we need a factory to make sugar? Can't we just use sugarcane directly?

While you can chew on a piece of sugarcane to taste its sweetness, the sugar inside is mixed with a lot of water and tough plant fibres. A factory process is needed to separate the pure sugar from these other components. The process removes the water and fibres, concentrates the sweetness, and turns it into the clean, easy-to-use crystals that can be stored and added to different foods.

5. How does the watery juice from sugarcane turn into solid sugar crystals?

The transformation from liquid juice to solid crystals is a process of concentration and crystallisation. When the juice is boiled, the water in it turns to steam and escapes, leaving the sugar molecules closer together in a thick syrup. As this super-concentrated syrup cools, the sugar molecules arrange themselves into an orderly, repeating pattern, forming the hard, shiny sugar crystals that we are familiar with.

6. Is the sugar in fruits the same as the white sugar we buy in shops?

While they are both sweet, they are different in how we get them. The sugar in fruits, called fructose, comes naturally packaged with water, vitamins, and fibre, which are good for our bodies. The white sugar we buy, called sucrose, is extracted and concentrated in a factory. It provides a lot of sweetness but does not contain the extra fibre and nutrients that whole fruits do.

7. What happens to the parts of the sugarcane plant that are left over after the juice is squeezed out?

The leftover fibrous material from sugarcane stalks is called bagasse. It is not wasted. This material is often used as a biofuel to power the sugar factory itself, making the process more energy-efficient. It can also be used to make paper and other eco-friendly products, showing how different parts of the plant can have important uses.