Why Is Tin Important? Properties, Uses & Everyday Examples

Tin is the fourth element of the fourteenth part of the periodic table. It is classified as a post-progress metal. Tin atoms have 50 electrons and 50 protons with 4 valence electrons in the outer shell.

Tin (Sn), a chemical element having a place with the carbon family, is Group 14 (IVa) of the periodic table. It is a delicate, silvery white metal with a somewhat blue tinge, known to the ancients in bronze, a combination with copper. Tin is generally used for plating steel jars used as food containers, in metals used for bearings, and in solder. The symbol of tin is Sn, an abbreviation of the Latin word for tin, stannum.

Atomic Number and Atomic Weight of Tin

What is Tin Metal?

Tin or also called Stannum in Latin with the atomic number 50 has a place with group 14 of the periodic table. Tin shows a chemical similarity to both of its neighbours in group 14, germanium and lead, and has two fundamental oxidation states, +2 and the somewhat more stable +4.

Properties of Tin

Under standard conditions, tin is a delicate silvery-grey metal. It is highly moldable (meaning it tends to be changed into a thinner sheet) and can be polished to a shine.

Tin can shape two unique allotropes under normal pressure. These are white tin and grey tin. White tin is the metallic type of tin we are generally familiar with. Grey tin is non-metallic and also a grey powdery material. There are a few purposes for grey tin.

Tin is resistant to erosion from water. Tin material permits it to be used as a plating material to protect different metals.

It is richly found like other elements like cobalt, copper, nickel, cerium, and lead.

The tin forms its oxide at higher temperatures when it reacts with water and oxygen.

Symbol: Sn

Atomic Number: 50

Atomic Weight: 118.71

Classification: Post-transition Metal

Phase at Room Temperature: Solid

Density (white): 7.365 grams per cm cubed

Melting Point: 231°C, 449°F

Boiling Point: 2602°C, 4716°F

Discovered by: Known about since ancient times

Uses of Tin

It is used in tin plating, covering, and polishing as it has a high resistance to corrosion.

It is used in the soldering of steel as it has high magnetic strengths and lower melting points.

It is used in the production of other alloy metals like Bronze and copper.

It is used as a reducing as well as a colouring agent for glass, pottery, and sensors.

In the delivery business, it is used as an antifouling agent for boats and ships to prevent them from leeches.

In dental applications, it is utilised in certain items as stannous chloride (SnCl2).

It additionally has its applications in the electrodes of batteries like in the Li-ion batteries.

It is broadly used in the production of food containers made of steel.

The parts of the tin today are to make solder. Solder is a mixture of tin and lead that is utilised to join pipes and make electronic circuits.

Tin is also used as a plating to protect other metals like lead, zinc, and steel from corrosion. Tin jars are actually steel jars covered with a plating of tin.

Different applications for tin include metal alloys, for example, bronze and pewter, the creation of glass using the Pilkington cycle, and toothpaste.

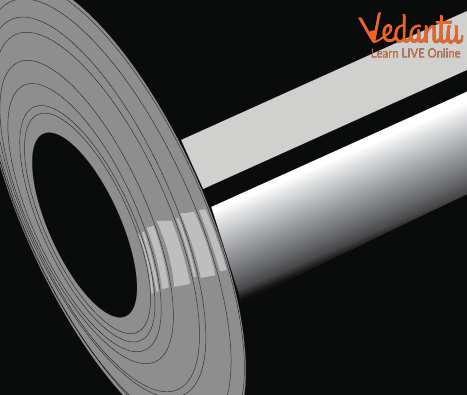

Thin Sheets Made Up of Tin

Container Made up of Tin

How did Tin (Sn element) Get its Name?

The symbol of tin i.e. Sn is an abbreviation of the Latin word for tin, "stannum"

Some Interesting Facts about Tin

When a lot of tin is crushed, it makes a shouting sound called a "tin cry". This is because of the breaking of the crystal structure of the atoms.

Pewter is a tin alloy that is something like 85% tin. Other elements in pewter include copper, antimony, and bismuth.

White tin will change into the grey tin when the temperature decreases below 13.2 degrees C. This is prevented by adding little impurities to white tin.

Bronze normally comprises 88% copper and 12% tin.

Summary

From the above discussion, we can summarise the following points.

Tin is a metallic chemical element, chemical symbol Sn, atomic number 50.

It is a delicate, silvery white metal with a somewhat bluish tinge, utilised since antiquity in the conventional type of bronze, its alloy with copper.

Since it is nontoxic, ductile, malleable, and effectively worked, it is utilised to plate steel cans ("tin cans") for use as food containers and to cover and plate different things.

Pure tin is too weak ever to be utilised alone, however, its many alloys include soft solder, pewter, bronze, and low-temperature casting alloys.

FAQs on Fascinating Facts About Tin

1. What are some of the most interesting facts about tin?

Tin is a fascinating element with a long history. Here are a few key facts:

- It is represented by the symbol Sn, from the Latin word 'stannum'.

- It has two main forms, called allotropes: the familiar silvery-white metallic tin and a powdery grey tin.

- Tin makes a unique crying sound, known as a 'tin cry', when a bar of it is bent. This is caused by the crystals inside the metal breaking.

- It was one of the first metals discovered and used by humans, leading to the historical period known as the Bronze Age.

2. What is tin primarily used for?

The most important use of tin is as a protective coating to prevent corrosion. It is used to coat steel for 'tin cans' used in food packaging. Tin is also used to make important alloys (mixtures of metals), such as bronze (tin and copper), pewter (tin, copper, and antimony), and solder (tin and lead), which is used for joining electronic components.

3. Why is tin so important for preventing rust?

Tin is highly resistant to corrosion and does not rust when exposed to water or air. When a thin layer of tin is applied to a metal like steel, it creates a protective barrier. This barrier stops oxygen and water from reaching the steel underneath, thus preventing it from rusting. This property is why it's ideal for food and beverage cans.

4. How is tin extracted from the Earth?

Tin is primarily extracted from a mineral called cassiterite (SnO₂). The process involves mining the ore, crushing it, and then heating it in a furnace with carbon. The carbon pulls the oxygen away from the tin, leaving the pure metal behind. Most of the world's tin is mined in a region known as the 'tin belt', which includes countries like China, Indonesia, and Malaysia.

5. If tin cans are coated with tin, what are they actually made of?

This is a common point of confusion. What we call a 'tin can' is actually made almost entirely of steel. A very thin layer of tin is applied to the inside and outside of the steel can. Steel provides the strength and structure, while the tin provides a non-toxic, corrosion-resistant layer that protects the food from reacting with the steel.

6. What was tin's role in the Bronze Age?

Tin was a crucial ingredient for one of the most important inventions in ancient history: bronze. By mixing about 10% tin with 90% copper, ancient civilisations created the alloy bronze. Bronze was much harder and more durable than pure copper, allowing for the creation of superior tools, weapons, and armour. This technological leap defined the Bronze Age.

7. Is tin a magnetic metal?

No, pure tin is not magnetic. It is a paramagnetic metal, which means it is very weakly attracted to magnetic fields, but for all practical purposes, you cannot pick it up with a common magnet. However, because 'tin cans' are made of steel, the cans themselves are magnetic due to the steel, not the thin tin coating.